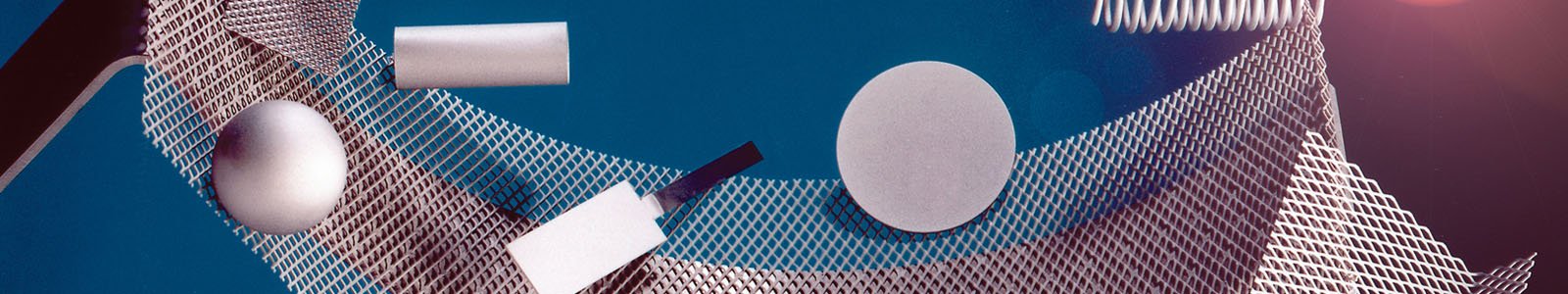

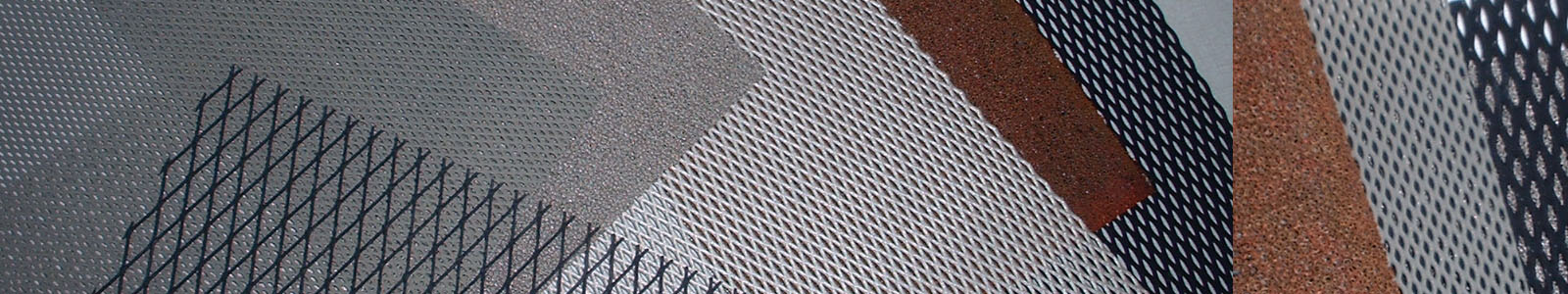

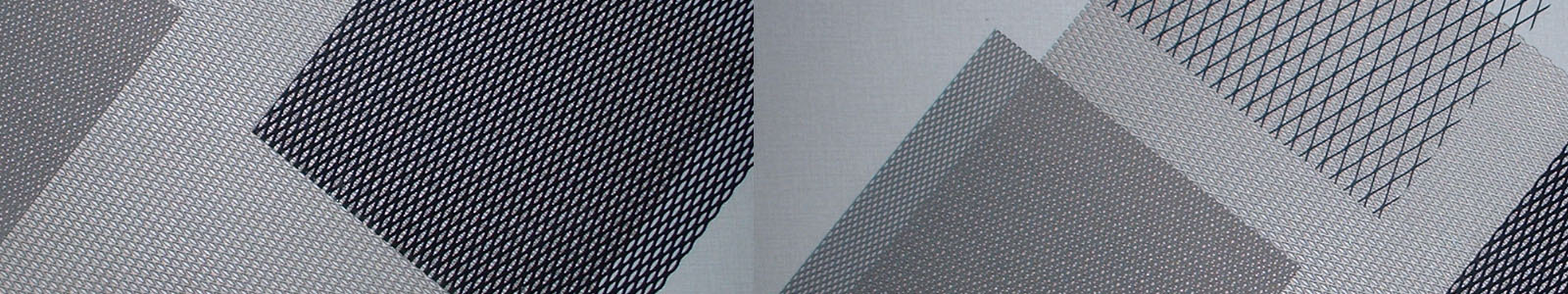

Insoluble anodes are composed of a titanium substrate coated with an electro-catalytic layer. There are two types of coating:

- platinum,

- based on mixed metallic oxides, commonly known as MMO.

These two categories of titanium anodes mean that high current densities from 50 to 600 A/m2 can be reached, according to the lifetime required, and the nature and conductivity of the electrolyte. This quality is all the more significant because it is combined with a low electrode overpotential.

In addition, the malleability of the substrate enables anodes to be custom-made and thus achieve a sizing as close as possible to the customer specification.

The TiMMO anodes were initially recommended as replacements for graphite and lead anodes in the 1960s.

Since then they have a proven track record in numerous other applications requiring on-site production of chlorine or oxygen in electrolytes with varying degrees of aggressivity (from pH 1-2 to pH 9).

In contrast with the so-called ‘soluble’ or ‘semi-soluble’ anodes such as those made from zinc, magnesium, graphite or ferro-silicon, the current passes by electronic transfer on the surface of the anode and so does not rely on the dissolution of the anodic material. Thus the titanium anode remains stable over time and does not constitute a consumable in the electrolytic cells (constant gap between electrodes) or in cathodic protection installations.

This feature gives them a considerable environmental advantage in the current climate where regulations on pollutant emissions are becoming more and more strict. Since titanium anodes are stable, there is no metallic leaching in the medium concerned and therefore no residual pollution.

However, anodes in platinum coated titanium are sensitive to acid pH and to residual ripple in the power supply and will be replaced by TiMMO anodes wherever possible.

In summary...

Insoluble titanium anodes offer:

- high corrosion resistance

- a wide range of current densities

- excellent dimensional stability

- custom sizing

- long lifetime

- respect for the environment